Manufacturing Solutions

Powered by LEAP Knowlogy, Smart Digitalization for Industry 4.0

Industry Challenges We Resolve

Transforming Challenges into Measurable Improvements

4M Traceability

High effort for compliance and auditing

OEE Productivity Measurement

Lack of Productivity Measure (poor OEE – Availability Rate, Performance Rate, Quality Rate)

Process & SOP Visibility

Poor visibility of processes and Standard Operating Procedures (SOPs)

Simplified Compliance & Auditing

High effort required for compliance and auditing

Inventory Visibility

Poor visibility and monitoring of inventory

Access Control & Change Management

Lack of Access Control and Change Management

Real-Time Shop Floor Visibility

Challenges Resolved by MES: Need for real-time visibility and improved shop floor performance.

Quality & Compliance Integration

Integration ensuring effective Quality Management and compliance adherence.

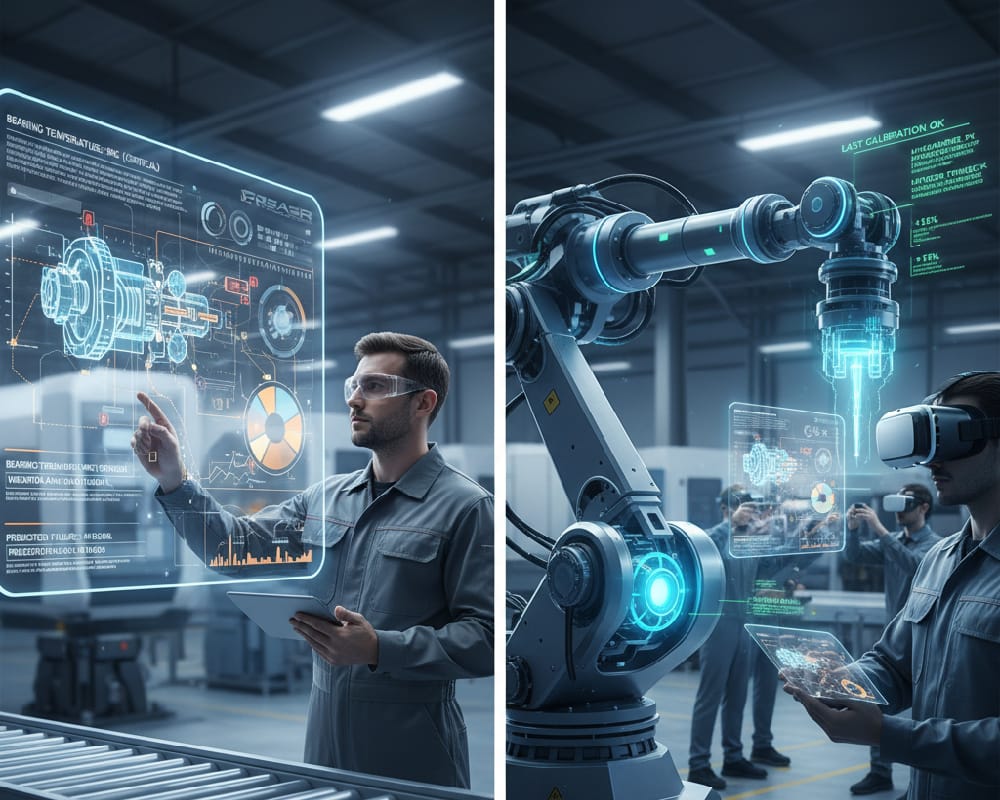

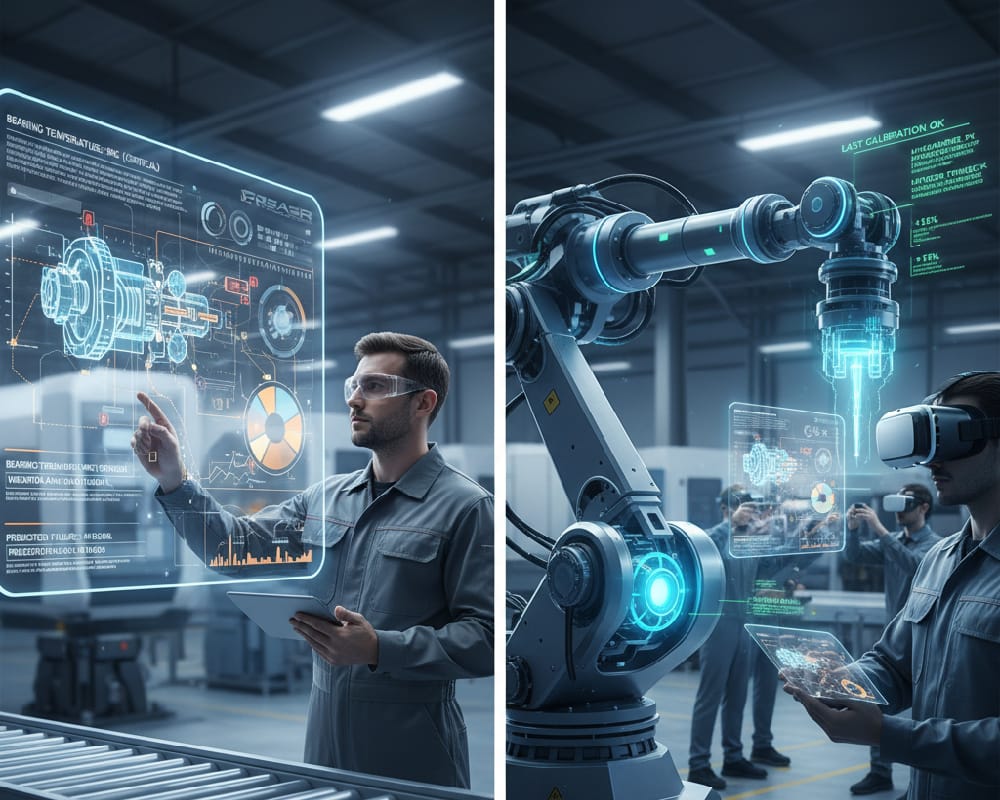

Core Technology Pillars

Smart Manufacturing & Industrial IoT (IIoT):

This includes using connected devices and sensors to monitor and optimize production processes in real-time.

Digital Twins:

This involves creating virtual models of manufacturing processes and equipment to simulate and optimize operations.

Predictive maintenance:

This includes using machine learning algorithms to predict equipment failures and schedule maintenance before breakdowns occur.

Augmented reality (AR) & virtual reality (VR):

This includes using AR and VR to improve training, maintenance, and troubleshooting.

Predictive maintenance:

This includes using machine learning algorithms to predict equipment failures and schedule maintenance before breakdowns occur.

Augmented reality (AR) & virtual reality (VR):

This includes using AR and VR to improve training, maintenance, and troubleshooting.

The Digital Solution

A Comprehensive Digital Solution

We help manufacturers achieve complete control through precise Monitoring, Tracking & Tracing, Analysing and Controlling. LEAP Knowlogy enhances operations across the entire value stream from raw material to finished product — ensuring measurable improvements in productivity, efficiency, and compliance.

Core Modules

Production Tracking & Control

Quality Management

Maintenance Management

Inventory and Materials Management

Labor and Management

Resource and Schedule Management

Reporting and Analytics

System and Data Management

Our Phased Approach

A Digital Transformation Roadmap

Our Offerings:

100% Paper-less Modules As per Automotive Standards IATF / VSA / VDA 6.3 / ISO

• Traceability, Work Instruction,

• Productivity, Production Planning, Inventory

• Access Control, Skill Matrix, Training,

• TPM & Tool Management,

• Quality : 4M Change Management, APQP and PPAP management system.

"SIMPLICITY IS COMPLEXITY RESOLVED"

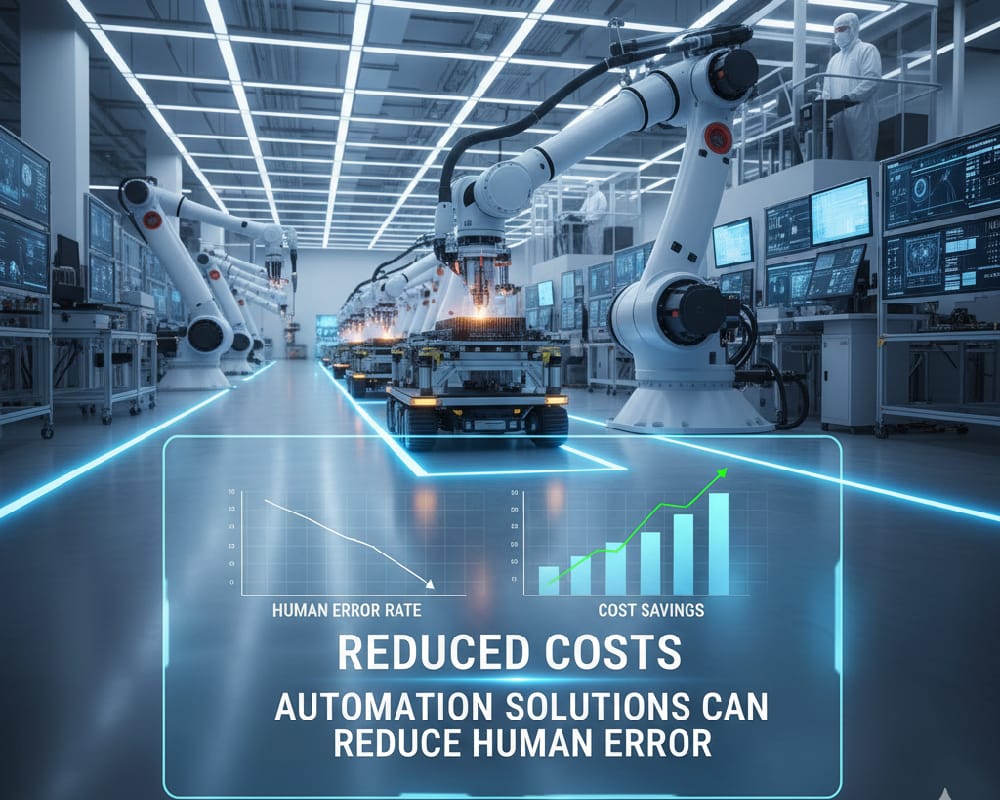

Key Benefits of Automation Solution in Manufacturing Industry

Improved Uptime

Increased Efficiency

Real-time Data & Traceability

Reduced Costs

Sustainability & Compliance